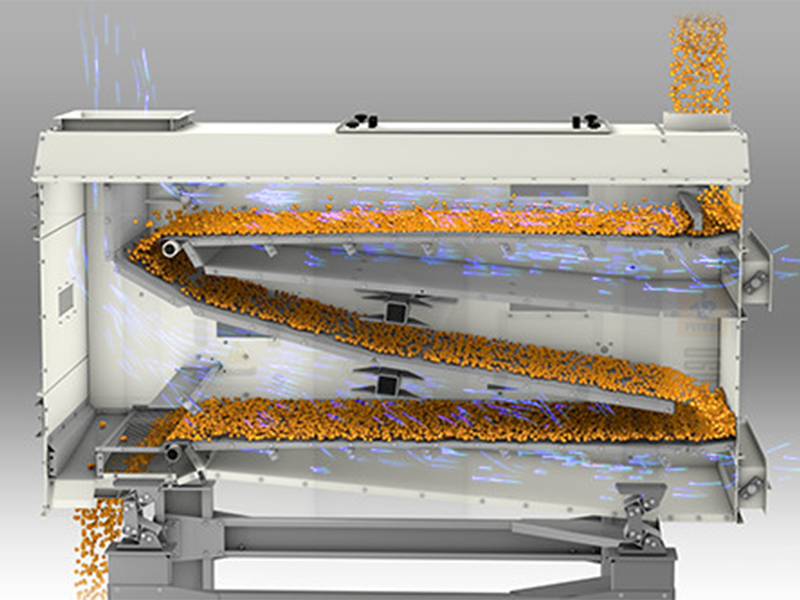

Fluidised Bed Dryer DF

Flexible, efficient and gentle drying have once again been successfully combined with efficiency and quality—all captured in one machine. Seed quality is negatively affected when too much moisture is absorbed during or after the coating and pelleting process, which often leads to clumping. Fluctuating weather conditions or high humidity can also lead to high moisture levels that impair seed quality. Without the use of a dryer, seeds can lose their best sowability and grain becomes stale and mouldy during storage. Gentle and efficient drying with the PETKUS DF guarantees that quality seed remains quality seed. The compact zig-zag design not only saves space, but increases flexibility: product can be fed in continuously, in batches, or in semi-batches. Furthermore, the temperature can be controlled at each level.

The compact PETKUS DF dryers dry product as it flows over zig-zagged levels, based on the vibrating fluidized bed principle. Counterbalance motors create a consistent and uniform vibration, while the air ensures a homogenous flow of goods. Warm air is blown in through two separate and adjustable flaps by a fan located at the side of the dryer and flows through the product in an upward motion. Four temperature sensors allow for optimal monitoring and control of the drying process.

Characteristics

- Flexible, efficient & gentle drying

- Compact design and small footprint due to z-shape drying loop

- Continuous, batch or semi-batch loading possible

- Separate temperature control possible for each drying level

- Counterbalance motors create a consistent and uniform vibration

- Variable product flow speed

- Temperature sensors for continuous monitoring and control

- Available with screens or Conidur® sheets

- Integrated quality assurance screen fan

- Preserves germination capacity & improves flowability

- Reduced abrasion

Technical Data:

| DF 090 | DF 120 | DF 150 | ||||||

| Capacity | (t/h) | up to 10 | up to 15 | up to 20 | ||||

| Working Area | (m2) | 3 | 4 | 5 | ||||

| Height | (mm) | 1900 - 2500 | ||||||

| Width | (mm) | 1260 | 1560 | 1860 | ||||

| Length | (mm) | 2570 | ||||||

| Screen | (mm) | 850 x 220 | 1150 x 220 | 1450 x 220 | ||||

| Weight | (kg) | 1300 | 1700 | 2200 | ||||

| Water Removal | (kg/h) | 100 | 150 | 200 |

Technical Diagram:

| Binbrook Hill |

| Binbrook |

| LN8 6BL |

| Lincolnshire |

| +44 (0)1472 398 498 |

| Copyright © Nickerson Brothers Ltd. 2024 All rights reserved |

| Company No. 01935311 |